Fraunhofer Institute for Building Physics IBP at BAU 2023

Times are challenging: not only have building materials become significantly more expensive in 2022, but the number of building permits for apartments has also fallen by almost seven percent1. Changes are also in store for the construction industry due to increasing digitization as well as higher requirements governing the energy efficiency of buildings or their indoor climate. New solutions from industry, politics and research are therefore urgently needed. At the BAU 2023 trade fair, which will be taking place in Munich from April 17 to 22, 2023, Fraunhofer IBP will be showcasing innovative products and system solutions on the topics of Digitization, Energy and Heat, The Future of Living and Working, and Resources and Recycling at the Fraunhofer Building Innovation Alliance booth (Hall C2, Booth 528) as part of the special exhibition “Building the Future”.

Focusing in particular on climate neutrality and the circular economy in the construction and housing sector, Fraunhofer IBP will be presenting future building solutions with ten exhibits. These will be on display at the Fraunhofer Building Innovation Alliance booth - more precisely, in and around the two-story Innovation Cube. This serves as a symbolic building to demonstrate novel solutions both for the building envelope and for the interior. The exhibits are spread across four topics: Digitization, Energy and Heat, The Future of Living and Working, and Resources and Recycling. From Tuesday to Friday inclusive, an informative lecture program will also be running for all interested trade fair visitors between 11 a.m. and 12 noon, and from 1:30 p.m. onwards.

Digitization

The climate is changing, with extended periods of high temperatures or severe storms becoming more and more frequent. This is especially problematic in urban areas because these react highly sensitively to such severe weather events. Cities must therefore be able to adapt in response to climate change and its effects. This is where advanced urban climate models such as PALM-4U come into play. Via simulations, they allow the urban climate to be experienced and enable clear conclusions to be drawn about climate change and urban climatic relationships. Municipalities, planners and project sponsors can use PALM-4U to study the impact of their planning measures on the climate and to communicate these measures to the public in a comprehensible and immersive way with the help of augmented reality applications.

Digitization also makes sense when it comes to key energy figures - in many cases, there is a difference between the energy figures forecast in advance and those actually measured. This is because data on the needs and behavior of the people using the building is lacking. The “DataFEE” project addresses this problem. In the project, the process chain for data use is being systematically developed and optimized with the aim of making building operation forecasts more dependable and of improving energy efficiency. The researchers collect the relevant data, process it and make it available in the form of models for planning tools and systems for operational management. Intelligent sensor technology, data mining, machine learning and predictive analytics support this process. The “digital twin” will also play a central role as a cyber-physical image of real devices and buildings. Based on the results, the researchers are developing services for building users and operators.

Again, this year, Mittelstand-Digital Zentrum Bau will be presenting its services for small and medium-sized enterprises in the construction and real estate industries at the Fraunhofer Building Innovation Alliance booth. The focus of the center, which is made up of four consortium partners from science and practice and is run by Fraunhofer IBP in Holzkirchen, is on the five topics of planning processes, construction sites, facility management, the optimization of digital business processes and the development of innovative transformation strategies. To this end, the center offers in-depth information brochures, events and digitization projects with goal-oriented roadmaps for resilient SMEs. Mittelstand-Digital Zentrum Bau is part of the Mittelstand-Digital Netzwerk, a network used by the German Federal Ministry for Economic Affairs and Climate Action to promote digitization in small and medium-sized enterprises and skilled trades.

Energy and Heat

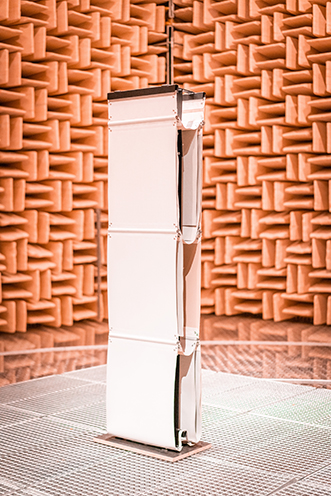

If the energy transition is to succeed, the rate at which buildings are currently being renovated must increase significantly - for example, by using more prefabricated building components. The Fraunhofer Institutes for Building Physics IBP and for Energy Economics and Energy System Technology IEE have developed a renewable energy module façade. The façade not only supplies the building with environmentally-friendly electricity but also heats, cools and ventilates the rooms behind. The heart of the module is a photovoltaic system, which is combined with a heat pump for heating and cooling as well as a decentralized ventilation unit with heat recovery - all of which are housed in the façade module. The system can be used to renovate existing façades as well as to equip new buildings with a sustainable and energy-efficient technology. The façade has a modular design and can be produced cost-effectively.

The Future of Living and Working

How can historic buildings be preserved sustainably and energy-efficiently? The Fraunhofer Center for Conservation and Energy Performance of Historic Buildings in Benediktbeuern is addressing this question by researching into innovative and lasting solutions. Among these is Fraunhofer IRB's continuing education program “Fachplaner/in nachhaltige Instandsetzung historischer Bausubstanz” (specialist planner for the sustainable restoration of historic buildings) under the brand name “QualiBene - Lernen und Qualifizieren am Fraunhofer-Zentrum Benediktbeuern” (QualiBene - learning and training at Fraunhofer Center Benediktbeuern). Aspiring specialist planners learn and acquire new skills in the Alte Schäfflerei building, which was restored from an energy perspective while retaining its status as a historic monument, and now serves as a showcase in the sense of a “transparent building site”. On the website www.denkmalpflege. fraunhofer.de, users can take a virtual tour, gain current insights into and retrospectives on the energy-efficient and conservation-friendly renovation of the Alte Schäfflerei, and also access a wide range of up-to-date information on research topics. The new section “Collect & Communicate Knowledge” provides access to Fraunhofer IRB building databases.

During the 1970s and 1980s, around three million buildings in Germany were treated with wood preservatives containing PCP and lindane to protect them from mold and insect infestation. Both substances have since been banned and are classified as carcinogenic and neurotoxic substances. In the CycloPlasma project initiated by Fraunhofer-Zukunftsstiftung, Fraunhofer IBP researchers are exploring ways to use the novel CycloPlasma process for decontamination purposes. The process combines an innovative adsorber material with plasma technology. The result: The CycloPlasma process can be used to treat both contaminated wood and interiors - sustainably, without leaving any residues and without posing any health risks. The research team is testing the approach in practice in an experimental setup on the grounds of the Glentleiten open-air museum.

Acoustics also play an important role in many people's lives - both in their working environment and in their leisure time. Reverberation in sports halls tends to be extremely high, especially in the middle section, which is often partitioned off from the outer parts of the hall by curtains. The noise level there is frequently extremely high, and in many cases, it is almost impossible to hear what people are saying. The innovative curtain called Sport-SAT, a sound-absorbing partition curtain designed especially for sports halls, alleviates this situation. Combined with sound-absorbing baffle walls and an absorbent ceiling, the partition curtain ensures very good acoustics in the hall sections and thus meets the requirements of DIN 18041 and DIN 18032. In short: Reverberation is reduced, noise levels are much lower, and speech intelligibility in the sports halls is greatly improved.

The new online-based software “reverberate” is an aid for calculating such reverberation times - especially in rectangular rooms with uneven absorber distribution. It uses a new computational method developed by Zhou et al. in 2021. Users can enter the geometry of a rectangular room and select the necessary specification values from DIN 18041. In addition, all room surfaces can be divided into sections and covered with absorbent materials, thus allowing the reverberation time to be calculated accurately.

Resources and Recycling

Heavy rainfall and the associated flooding are increasingly dominating the headlines. If they cause water damage in homes, until now there was hardly any way around noisy and power-hungry drying systems to get walls dry again. Researchers at Fraunhofer IBP have developed a much more energy-efficient and faster alternative in the form of FastDry®: The drying technology requires only about 15 percent of the energy needed by standard infrared devices for the same process. The operating temperature is typically around 55° Celsius. And, especially important for the people living in the building, since neither a fan nor a compressor are used, the FastDry® units operate silently. The innovative drying module consists of a large, rectangular insulation panel made of commercially-available, non-combustible mineral wool that is laminated on both sides. It is mounted directly to the damp wall and heats it by means of an integrated heating wire. While the insulation keeps the heat in the wall, water vapor can escape unhindered through the permeable module.

Insulation materials are essential if the required reduction in CO2 emissions is to be achieved quickly. However, they must be produced sustainably and remain in the material cycle at the end of their useful life. Loose fill insulation is considered particularly efficient: the materials used require little preprocessing and can also be easily integrated into production processes. Ecological loose fill insulation based on materials containing lignocellulose offer a number of advantages in this respect. Besides being locally available from residual material streams, the properties of the insulation material can be optimized for different application scenarios by adapting the filling material. Via an alkali-activated biocarbon composite, the stiffness of the lignocellulose fiber is lastingly adapted and additionally paired with a carbon capture effect. Together with the partners Baufritz and CarbonInstead, the concept has already been implemented on a pilot scale. The recently launched SchüttliBi 2.0 project aims to roll out its use on an industrial scale.

Aerated concrete also has excellent thermal insulation properties, and scores with its long service life and good acoustic properties. Researchers at Fraunhofer IBP are therefore working on using more alternative raw materials to manufacture aerated concrete and on making it easier to recycle. The focus is mainly on primary raw materials that have a high CO2 impact, such as cement. The aim is to replace these without impairing the good insulating properties of the building material. Computer-aided models are used to systematically optimize the formulations for climate-friendly aerated concrete. Fraunhofer IBP also has the necessary technical equipment to further develop aerated concrete from the formulation stage through to pilot-scale production.

<sup>1</sup> Source: https://www.destatis.de/DE/Themen/Branchen-nternehmen/Bauen/_inhalt.html

Further Information

Last modified: