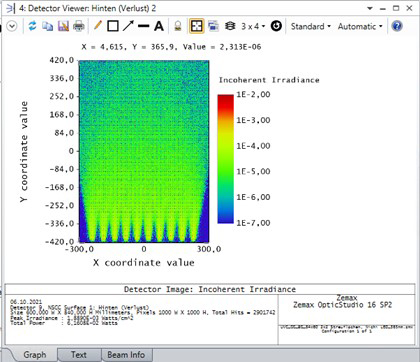

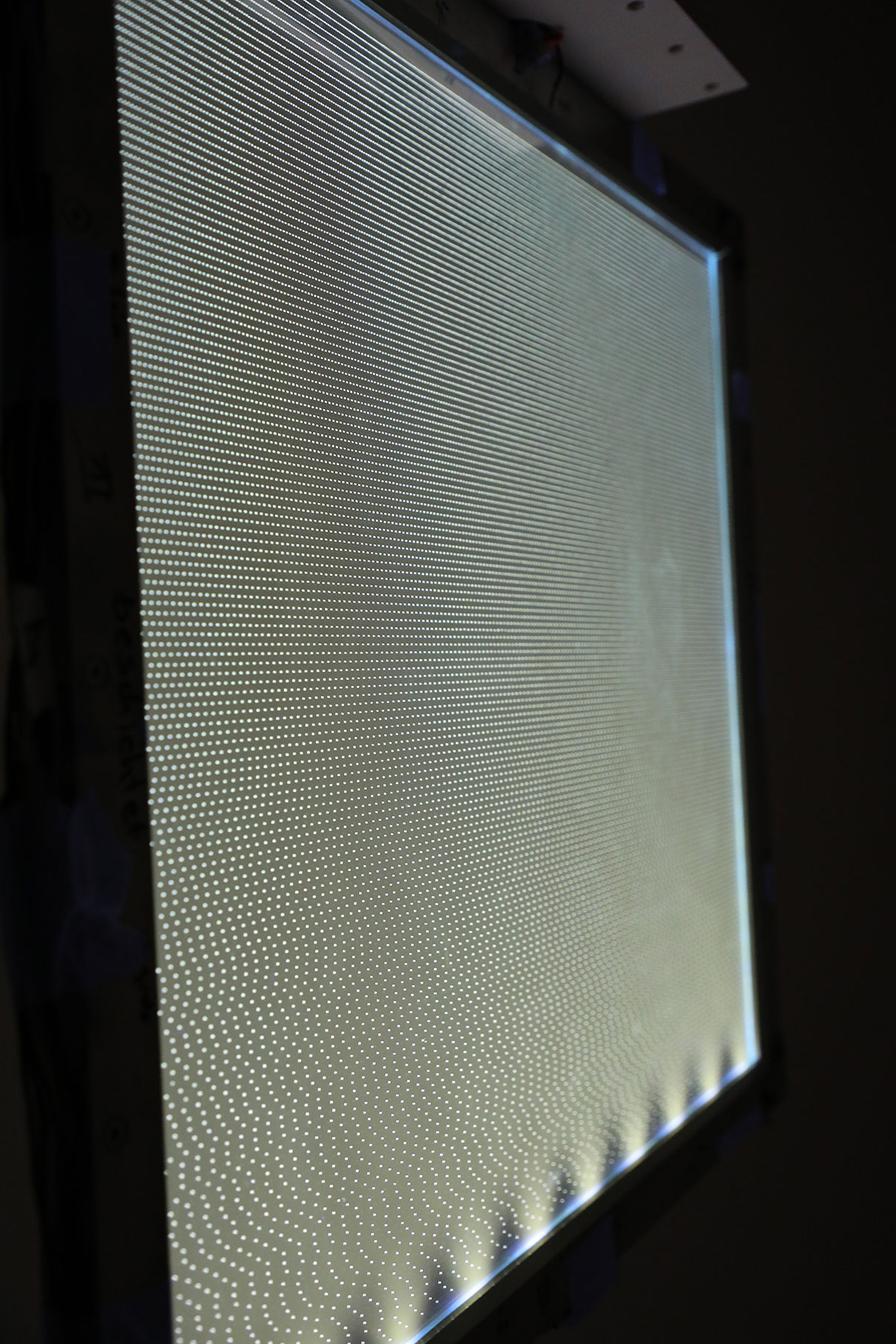

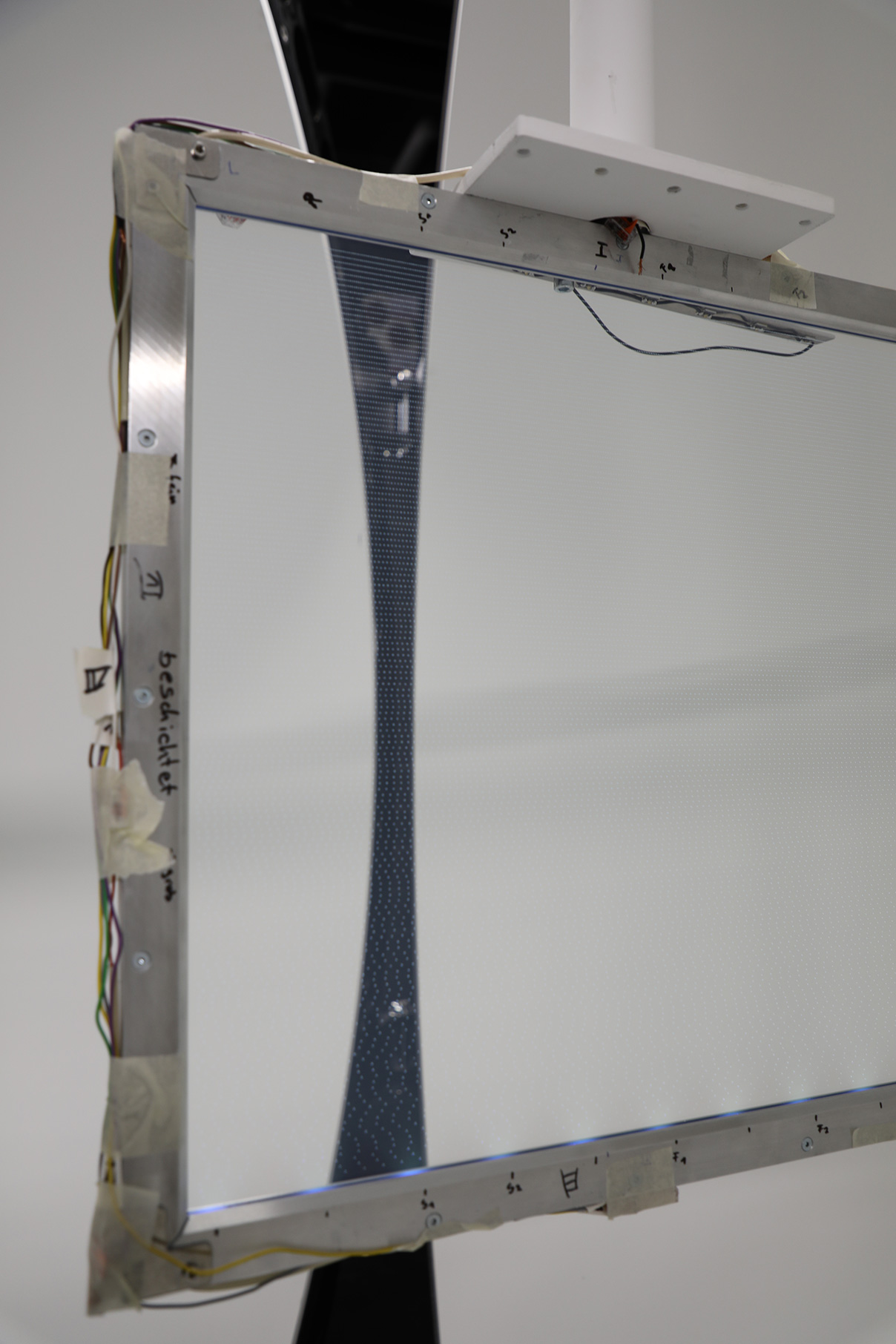

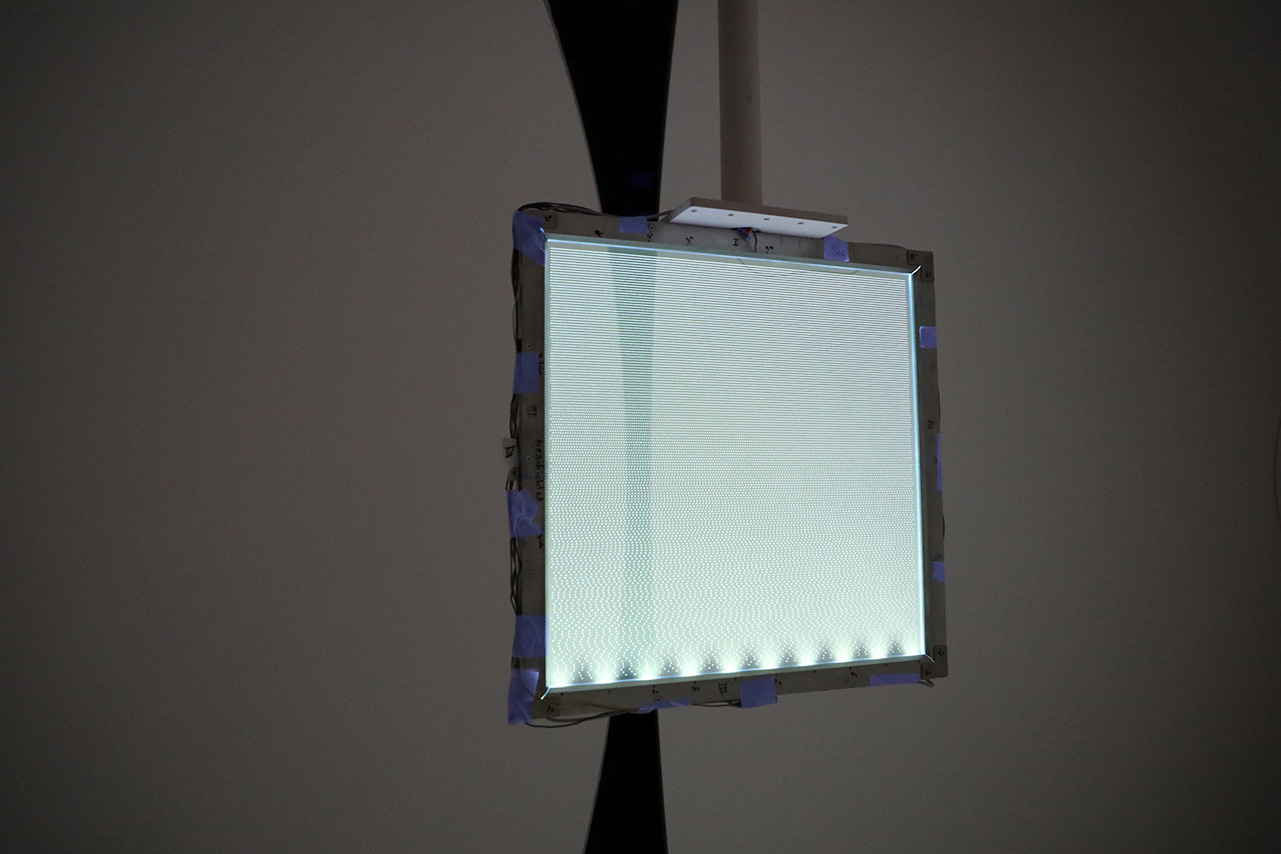

Effective disinfection technologies have been an important topic not only since the Covid-19 pandemic but have increasingly been in the public spotlight since then. The basic idea of this project was to further develop a glass coated with titanium dioxide (TiO2), which generates reactive oxygen species through a photocatalytic process and thus reduces the viral and bacterial load, into a practically applicable transparent virus protection element. Fraunhofer IBP, in collaboration with Fraunhofer IGB and other project partners, has developed a product-oriented prototype that increases this effect through edge-coupling of UV-A radiation via LEDs and laser microstructuring. The virus protection glass can improve hygiene at sales counters, in kitchens, in refrigerators as well as in the medical field.