Aeroacoustic tests on air vents

THE SOUND OF SILENCE - acoustically optimized air vents in vehicles

Small vent - big impact

When developing new vehicles, car manufacturers aim to maximize comfort for their customers. The acoustics inside a vehicle play a decisive role when it comes to the well-being of the occupants. To minimize unpleasant sources of noise, the design and interior of vehicles are continuously being further developed. With the advance of electromobility, vehicle drives are also becoming quieter and quieter. In electric vehicles, the typical noise associated with combustion engines no longer exists. As a result, the focus has shifted to sources of noise inside vehicles that used to be less important. What was previously drowned out by engine noise is now perceived as annoying. Air vents are a typical example of such a source of noise. Depending on where the outlet grille is located, the airflow can cause an unpleasantly loud noise or an irritating whistle.

Simulating instead of testing

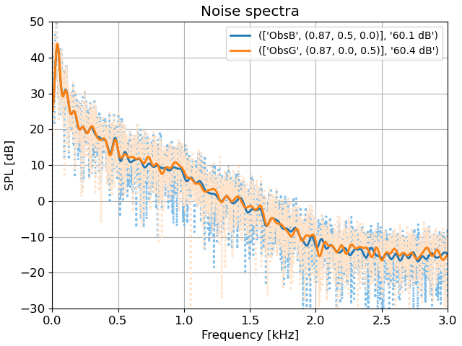

To acoustically optimize a component such as an air vent, prototypes are usually built and analyzed in test series. This is invariably a time-consuming and expensive procedure that, fortunately, can now be achieved in a much smarter way with Computational Aeroacoustics (CAA), a method which simulates airflow noise. CAA simulations can be used, for instance, to predict the noise generated by air vents as a function of their geometry and the flow velocity. This means that a good compromise between design and acoustic comfort can be found at an early stage in development, saving both time and money.

Solution

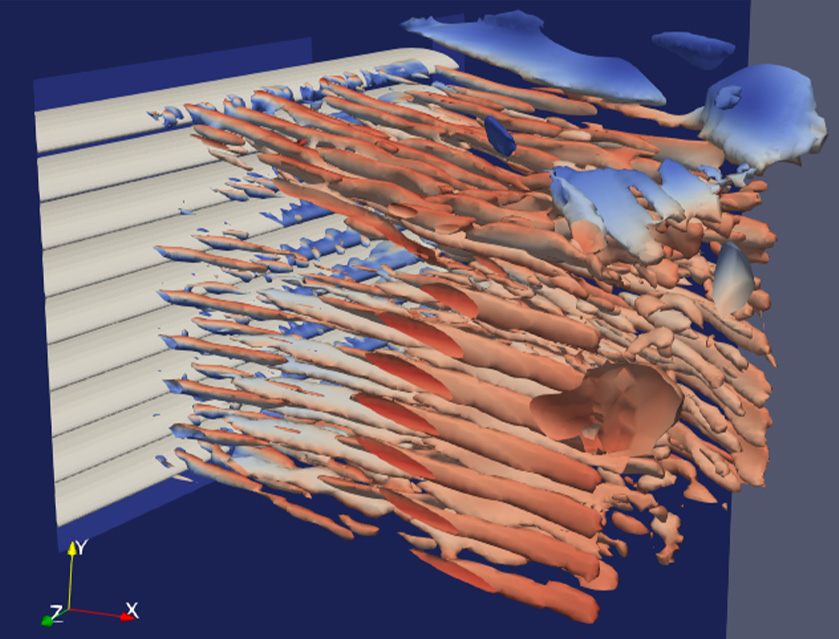

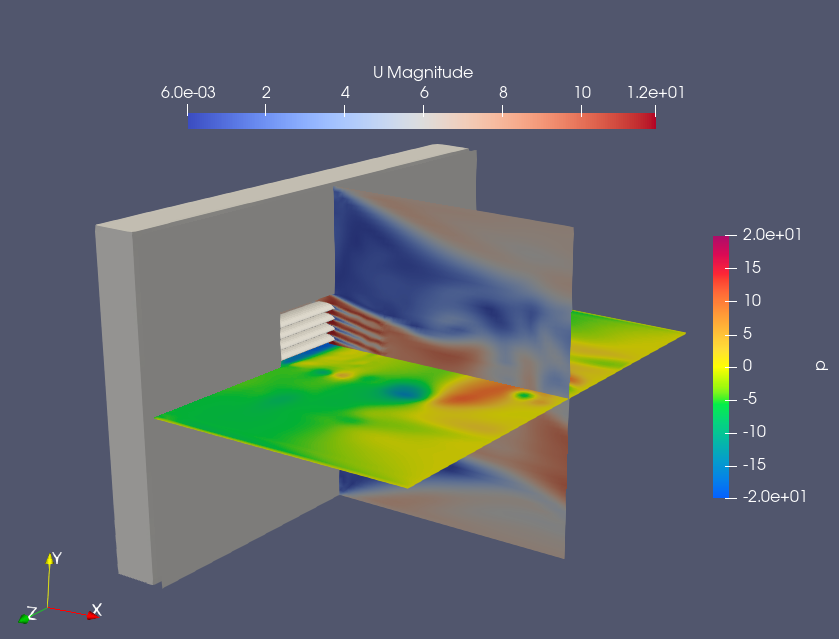

On behalf of automobile manufacturers and their suppliers, the Fraunhofer Institute for Building Physics IBP studies and optimizes the airflow and aeroacoustics of air vents. Transient RANS methods are utilized to calculate the turbulent flow field and aeroacoustic sources at the air vent. To do this, the Ffowcs Williams-Hawkings method is implemented. The results can be used to estimate the corresponding sound pressure levels in the vehicle interior. This procedure allows a high number of possible geometries to be investigated and optimized, taking into account manufacturers’ specific requirements.

Order processing

- Order clarification

- Geometry definition

- Simulation

- Optimization if required