Sintered open-pored inorganic foams - a contradiction?

Diverse demands from industry for fiber-free absorber materials for immission control have given rise to the development of new open-pored materials. As early as in the 1980s, a mineral-organic gypsum foam made from water, a prepolymer and FGD gypsum generated as a by-product from flue gas desulphurization (FGD) was developed. This material is now successfully used as a sound absorber in office partition wall systems.

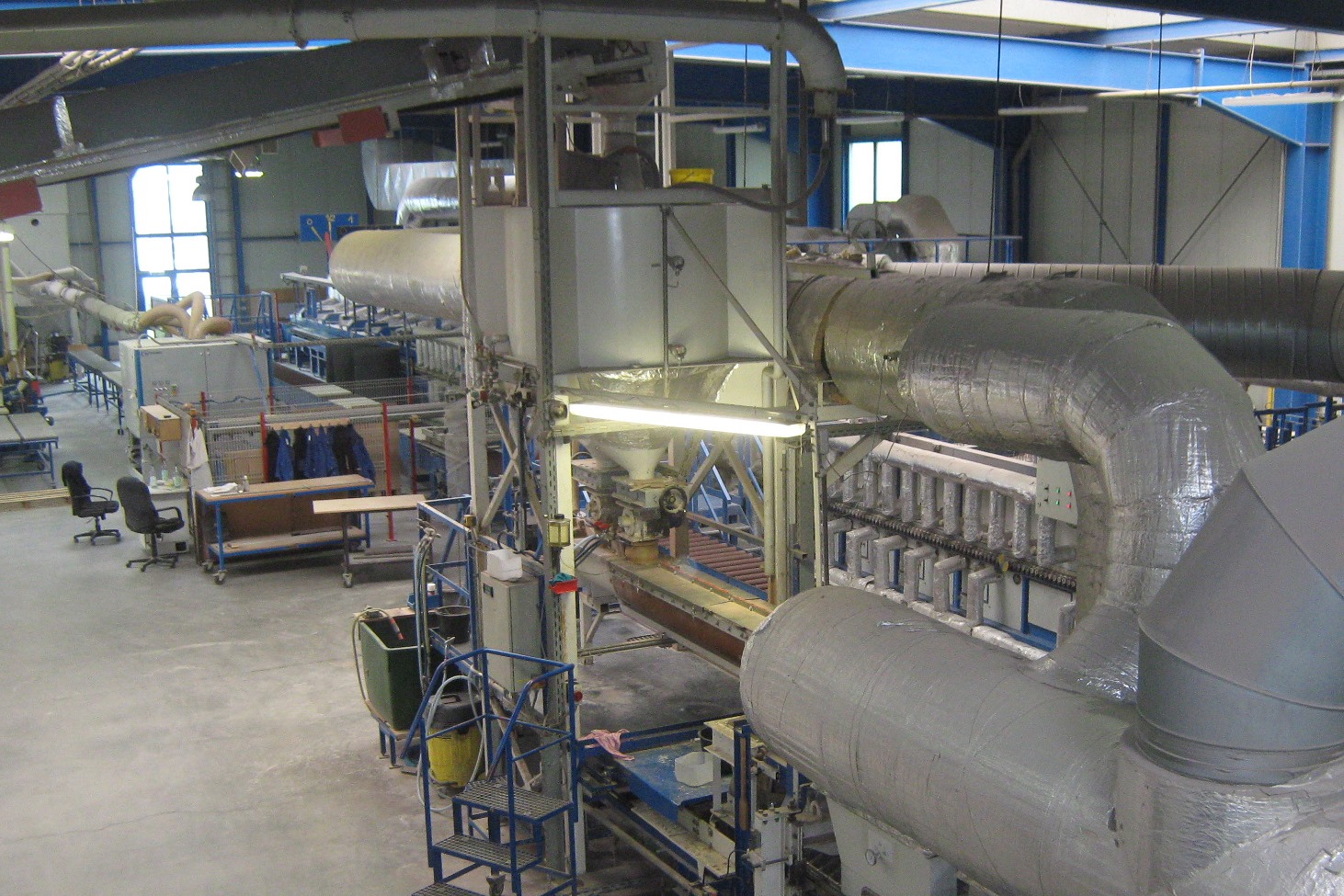

In recent years, a process has been developed to produce non-combustible, inorganic foams (REAPOR®) with a defined, variable micro-pore and macro-pore structure. As a result, the properties of the foams can be adapted to an extremely wide range of requirements.

These lightweight materials are mechanically resilient, non-combustible, recyclable and easy to process. They also have a high sound absorption capacity, low thermal conductivity and exhibit good chemical resistance properties. By being able to design the pore structure of REAPOR® in a specific way, products such as broadband sound absorbers for fixed rail vehicle tracks or wall panels with good thermal insulation properties can be manufactured.