Environmentally compatible product development

Pathbreaking design

Design for Environment (DfE) or eco DESIGN constitutes the basis for integrating ecologically relevant aspects into the design and development processes of products and product systems. On the basis of Life Cycle Assessment data, design modifications and ongoing product development can already be examined in advance in terms of their ecological impact. Environmentally appropriate design variants can be devised under consideration of technical and economic requirements, for example with regard to the choice of materials and processes, and technical feasibility. Analysis of the entire product life cycle is crucial in order to prevent a shift of ecological problems across the individual phases of the life cycle. The development-oriented approach of eco DESIGN enables the potential ecological impact and possible risks to be identified throughout all phases of product development. On this basis, ecologically unfavorable solutions can be identified at an early stage and suitable optimization measures derived.

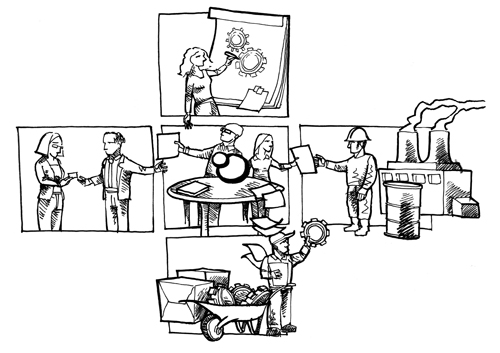

Ecological improvement to a product is only possible with the inclusion of all parties involved in development – from the supplier, to the planning and development departments, up to production management. It is therefore important that all findings and necessary measures be communicated in a manner this is readily understandable to all involved and that an exchange take place between the various competencies.

For product development, this means that all relevant ecological aspects must be translated into the language of the designer on the basis of their dependent technical parameters. This information can take several forms, for example as checklists or guidelines. Unlike purely qualitative eco DESIGN methods, the processes supported by Life Cycle Assessment (LCA) make for targeted, product-specific improvement measures that can already be quantified in advance with regard to their ecological impact.

The Life Cycle Engineering Department not only provides support in decision making for the development and design processes, but also draws up flexible Life Cycle Assessment models of product systems attuned to the specific requirements; these allow design modifications to be quantified in an uncomplicated process. Reliable statements can also be made about the ecological profile, weak points, and measures for improvement of possible design options for the product in question.