External noise is largely transmitted into buildings via windows and glazing. This is because they have poorer sound insulation properties compared to external walls and also due to the growing proportion of glass used in modern architecture.

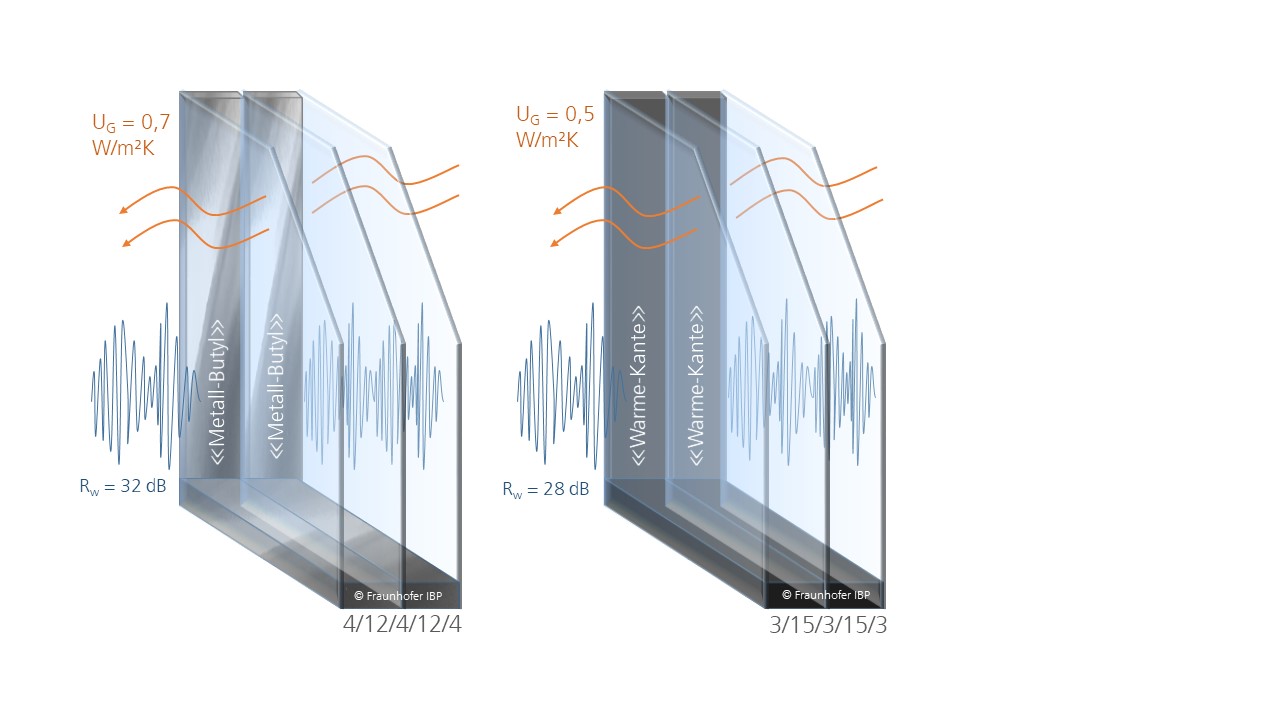

Problems arise when planning sound insulation for buildings if manufacturers have the sound insulation of their products tested according to DIN EN ISO 10140 using only a normed installation surface and an aluminum-butyl edge seal. However, the sound insulation properties of glazing depend to a large extent on the pane format, the choice of warm edge spacer and other factors. When developing modern thermal glazing, the focus is increasingly on optimizing thermal insulation, while ignoring the consequences for sound insulation. The Building Acoustics Working Group at Fraunhofer IBP wants to change this.