Fermenting biomass to generate biogas from organic sulfur compounds

...is anything but easy. The main difficulty lies in controlling the process because biomass is heterogeneous by nature. To date, extensive gas purification and enrichment methods have been required to process biogas. In order to optimize this process, the complex biological, chemical and physical parameters and fermentation steps involved must be known and understood in detail.

Scientists at Fraunhofer IBP are therefore developing online process analytics to detect and prove the presence of organic sulfur compounds. The Federal Ministry of Education and Research (BMBF) funded this joint project “Online process analysis of parameters influencing quality in biogas production using intelligent sensor technology”.

In their work, the scientists focused on three main areas

- They studied a large urban wastewater treatment plant, a regional biowaste disposal system and an agricultural poultry farm, all with different process technologies and biomass types. Does the formation of organic sulfur compounds occur?

- Are metal oxide sensors suitable for detecting such organic sulfur substances? The scientists also further developed the sensors.

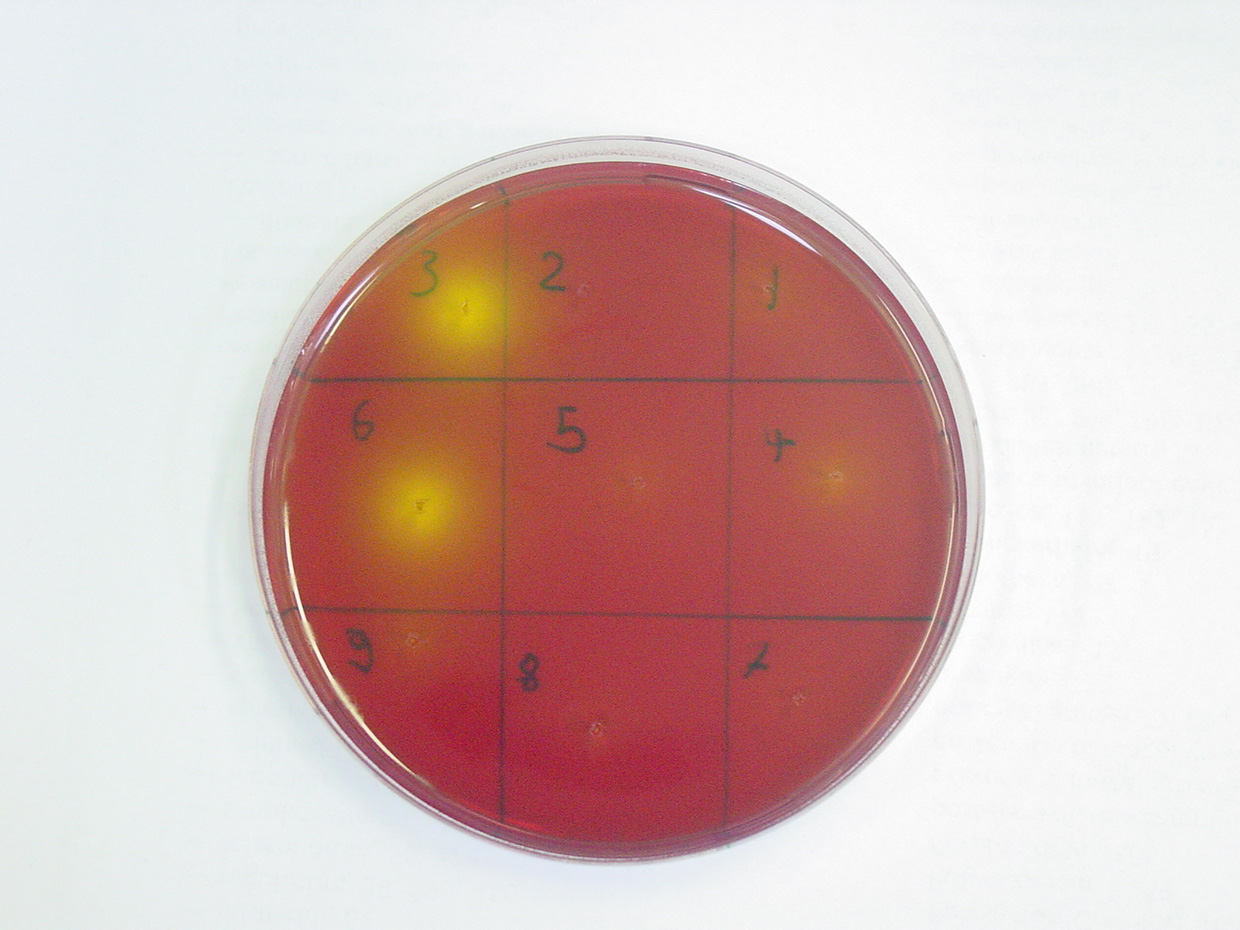

- In an analytical laboratory study, they were able to identify which organic sulfur precursors are relevant with regard to the formation of hydrogen sulfide (H2S).

Since the biogas process is highly complex, the resulting gas mixture varies. A particularly undesirable by-product is hydrogen sulfide (H2S): Apart from having an unpleasant smell, it is also toxic and corrosive. H2S is at the end of a chain of degradation products from organic substrates. The researchers identified key base materials and intermediate products and clarified the relationship between the formation of hydrogen sulfide and microbial activity in the substrate. If biogas fermentation takes place strictly anaerobically - i.e. without air - thiols are formed. If, on the other hand, sulfides are formed, this indicates an aerobic influence - i.e. that the process takes place in the presence of air.

If organic sulfur compounds are formed, this also affects the process. A purpose-built sensor developed by the scientists allows the control technology to intervene in the fermentation process. Therefore, situations arising during the biogas process in the future that are out of control can be prevented, regardless of the substrate used. The technology adapted by the researchers for the project is based on doped and undoped ceramic semiconductor gas sensors with appropriately-modified measuring and control systems. These were validated on a gas test bench.

For subsequent signal acquisition, the scientists used selected sensors on the laboratory fermenter and were thus able to reproduce different operating states in order to evaluate the sensors. The sensors were capable of detecting changes in the process control. By monitoring the formation of organic sulfur compounds and using them as marker substances for the fermentation process, the researchers were able to determine optimal fermentation conditions and produce high-quality biogas.