Testing air permeability

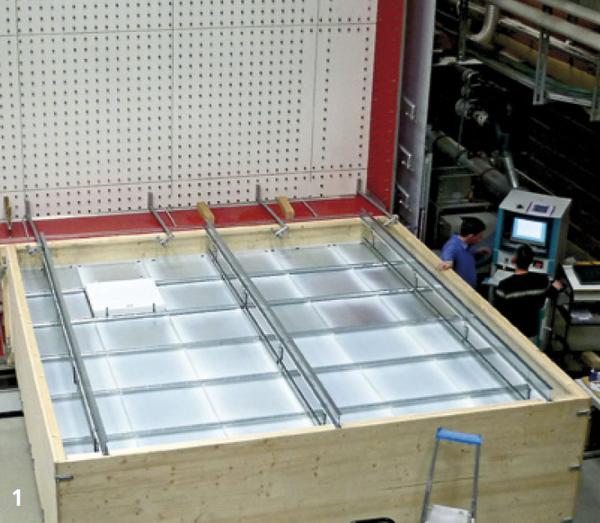

Our growing dependence on electronic equipment, both for use in industry and in daily life, means that ever-more cleanrooms are needed by companies such as microchip manufacturers. Strict requirements are placed on the exchange of air inside cleanrooms. Therefore, it is crucial that the systems used in their construction meet exacting air permeability criteria. On behalf of industry, Fraunhofer IBP investigated the air tightness of suspended ceiling systems for the first time specifically for cleanrooms. The suspended ceilings were expertly installed in their usual position in a specially designed test box. Air permeability was tested with pressure differentials ranging from -5 Pa to -50 Pa and +5 Pa to +80 Pa, allowing researchers to calculate the air permeability based on the surface area and joins of the ceiling panel being tested.

The evaluation was based on an existing system used to classify and assess the air tightness of doors and windows. This system distinguishes between four classes of air tightness; within each class, the boundaries are defined by the maximum permissible air permeability at a certain pressure in dependence on ace area and length of the joins. In order to have a point of reference (to compare products, for example), the reference air permeability values for windows are based on a pressure differential of 100 Pa.

To test the cleanroom ceilings, however, the reference air permeability taken as a practical point of comparison was based on a pressure differential of 30 Pa, reflecting realistic cleanroom conditions.