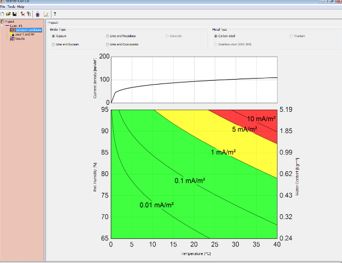

Usually, the reinforcing steel is protected against corrosion due to the alkalinity of the concrete. When carbonation occurs, this protection can get lost. While carbonation is fast in dry concrete and much slower in moist or wet concrete, corrosion behaves conversely. Whereas calculation models for carbonation are already available, they are missing for the transient prognosis of the corrosion progress with respect to the temperature, humidity, time and corrosivity of concrete. In addition to that, detailed material properties for the time dependent liquid and vapour transport in the different areas of concrete are required. Up until now, effective properties for the transfer through the concrete layers seemed to have been sufficient for the moisture resistent material.

On the basis of these investigations, both hygrothermal simulation tools and evaluation models will be developed. These will enable the prediction for any application and operation concerning the questions of whether and to which extent a corrosion risk of the reinforcement has to be feared, and how this can be prevented. For instance, by changing assembly or materials, or by adding coatings. For that purpose, normal, recycled, and CO2-absorbant concretes are considered.

Owing to the new prediciton possibilities, corrosion problems can be avoided, as well as allow to both develop cost efficient refurbishment measures and to extend the use of recycled concrete while improving the carbon footprint of concrete structures.