Plastering exterior walls is a traditional craft that has developed over centuries based on experience with locally-sourced wall building materials, binders and additives. It was only about 100 years ago that rendering became a subject of scientific research. This was prompted by an increase in plastering problems that coincided with a radical change in building methods: walls were now being constructed using large blocks of lightweight concrete instead of small solid bricks laid in courses consisting of alternate stretchers and headers.

The first research dates back to the 1940s, when surveys were conducted throughout what was then the German Reich to document the plastering techniques commonly used in different areas of the country (structure/layers, binding materials, grade of sand). This was the first step toward the start of plaster/render research. The results were published in 1950 in a book entitled "Außenputz für Massivwände" (author F. Kaufmann, Bauverlag Wiesbaden). In the guidelines derived from this, it is stated that:

"The initial coat of render must be sufficiently damp and rough to provide a key when applying the final coat. The final coat may not be harder than the undercoat."

This requirement was subsequently reformulated and incorporated in DIN standard 18550, published in 1955, as follows:

“As a basic rule, the initial coat of render must be at least as hard as the final coat.”

When a revised version of the standard was published 30 years later (DIN 18550-2, 1985), the sentence was reworded as follows:

“The hardness of the final coat should normally be lower than that of the undercoat, or the hardness of both layers should be equal.”

The following requirement was also added:

“This rule applies by analogy to the relationship between the hardness of the underlying masonry surface and that of the initial coat of render.”

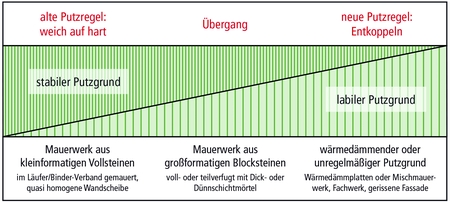

These plastering rules (sometimes referred to as “soft on hard”) are based on the experience of generations of craftsmen who only knew solid masonry. These rules are still being followed to the letter by mortar manufacturers to this day, and any products that deviate from them are reluctantly approved as “exceptions” if they stand the test. In the meantime, however, the criteria used to judge the performance of building systems for external walls have changed. The focus is no longer on load-bearing capacity and stability, but on thermal insulation. Modern building techniques call for large-format lightweight masonry blocks that provide a high level of thermal insulation with thin mortar joints that minimize thermal bridging effects. To a certain extent, this makes walls less stable and the plaster has to compensate for any deformation that might occur. To prevent cracking, it must be capable of accommodating changes in the underlying surface. At the same time, priority is given to other aspects in new render systems that have been developed to provide specific functional properties. This development is described in the publication "Changes in the requirements and execution of exterior plasters" [1].

Development of render systems

Fair-faced render

The older types of render for conventional masonry, which mainly serve decorative or finishing purposes, can be classified as fair-faced render, by analogy with the term "fair-faced brickwork" for non-plastered walls. The stipulations in DIN 18550 relate mainly to these types of render

Water-repellent render

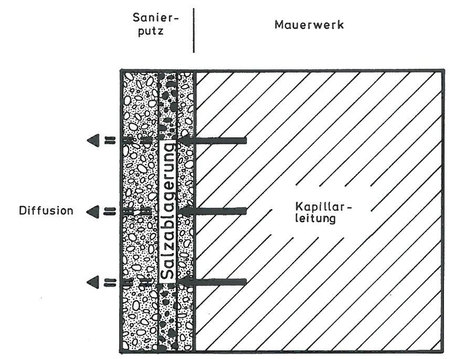

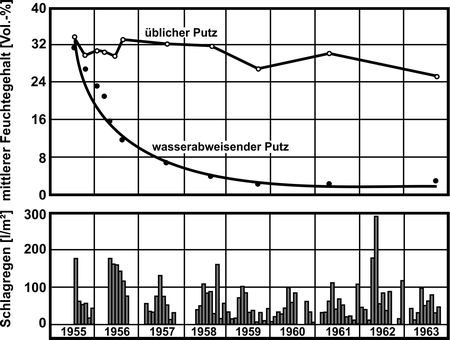

It is impossible to produce a sufficiently reliable hydrophobic render from hand-made mortar made with binding materials and sand at the building site. It was only when factory-mixed mortars composed of precisely dosed ingredients and additives came into widespread use that it became possible to make truly water-repellent plasters. After extensive studies to determine the necessary hygroscopic properties of render systems, two key characteristics were defined, namely the water absorption coefficient w and the diffusion resistance sd. These characteristics may not exceed specific values [2]. After many years of field tests and technical reviews, the requirements for water-repellent render were officially standardized in DIN 4108-3 (1981) and DIN 18550-1 (1985), which classify these and other special coating systems according to the required protection against rain. The example in Figure 1 compares the effect of a water-repellent render with a lime cement render.

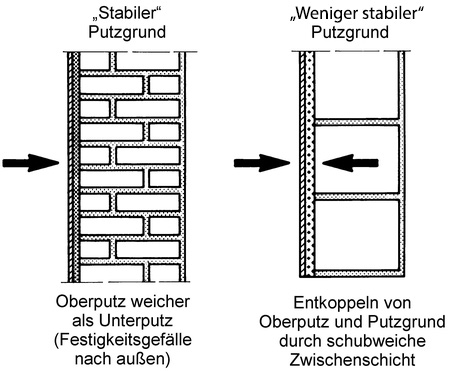

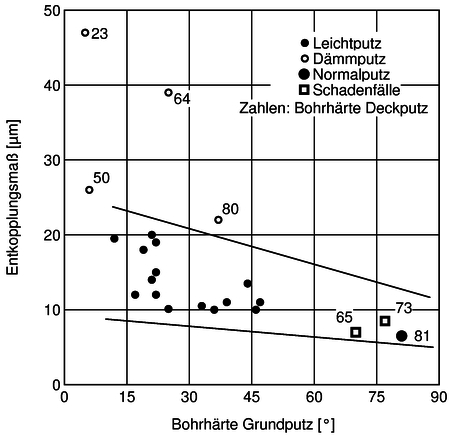

Flexible, crack-resistant render

The aforementioned “instability” of walls made from large-format blocks with thinner layers of mortar was first observed in walls built with lightweight and porous concrete blocks. Initially it was thought that the damage was due exclusively to the concrete blocks shrinking. The above-mentioned 'instability' in masonry made of larger blocks with 'sparing' grouting initially occurred in particular in walls made of lightweight concrete and aerated concrete blocks, with shrinkage of the blocks being assumed to be the sole cause of the damage. But later, when similar cracks also started to appear in plastered walls made of porous lightweight bricks, which was attributable to the bricks' heterogeneity, it was recognized that the cause of cracking in all of these cases was due to differences in the standard compressive strength and shear strength or transverse motion of the masonry [1]. The basic difference between the traditional stable base for rendering and today's less stable base of lightweight blocks is shown in Figure 2. If the underlying structure is stable, the render is normally only exposed to external stress due to the weather. However, if the underlying structure is less stable, the render may also be subjected to tension stress caused by dimensional changes in the masonry, which may lead to cracking. To prevent visible cracks from forming in the final coat of plaster, an intermediate layer of low-shear-strength material must be applied between the surface of the masonry and the topcoat of plaster. Lightweight base renders compliant with DIN 18550-4 have proved suitable for this purpose. Existing studies show that the softer the base coat and the harder the final coat, the greater the anti-crack effect - in other words, it equates to the rule of “hard on soft”, as illustrated in Figure 3.