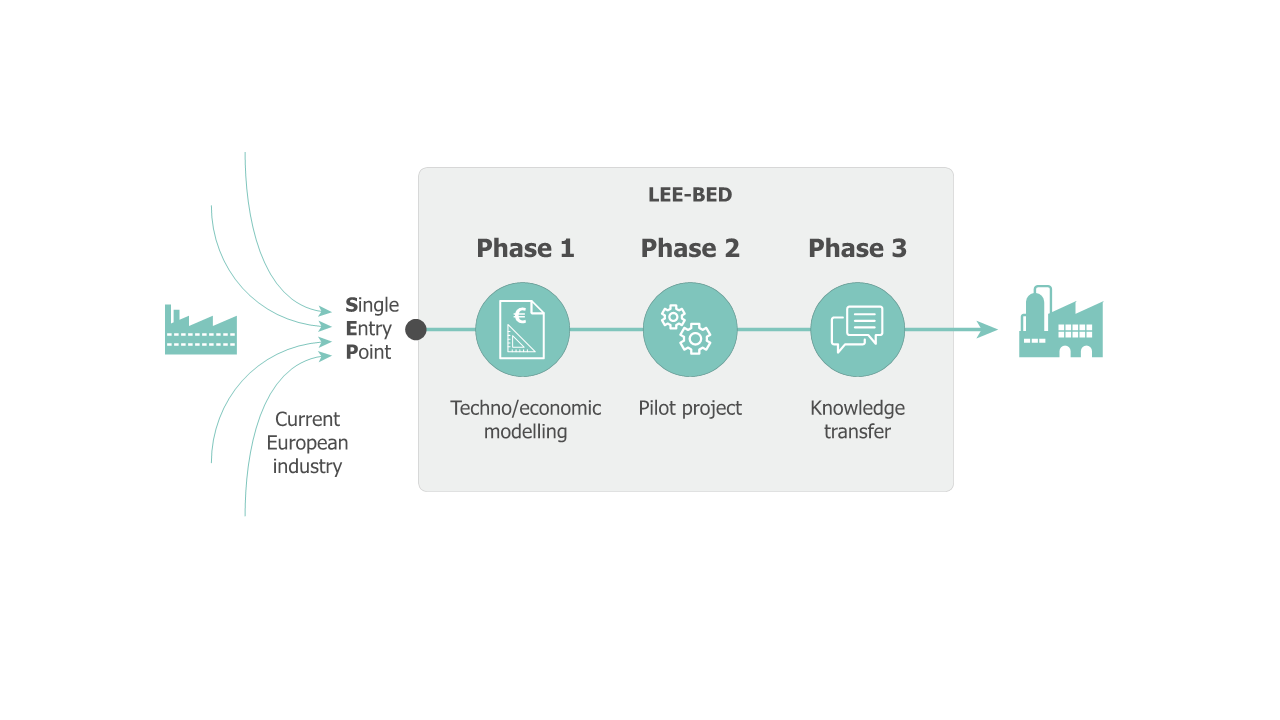

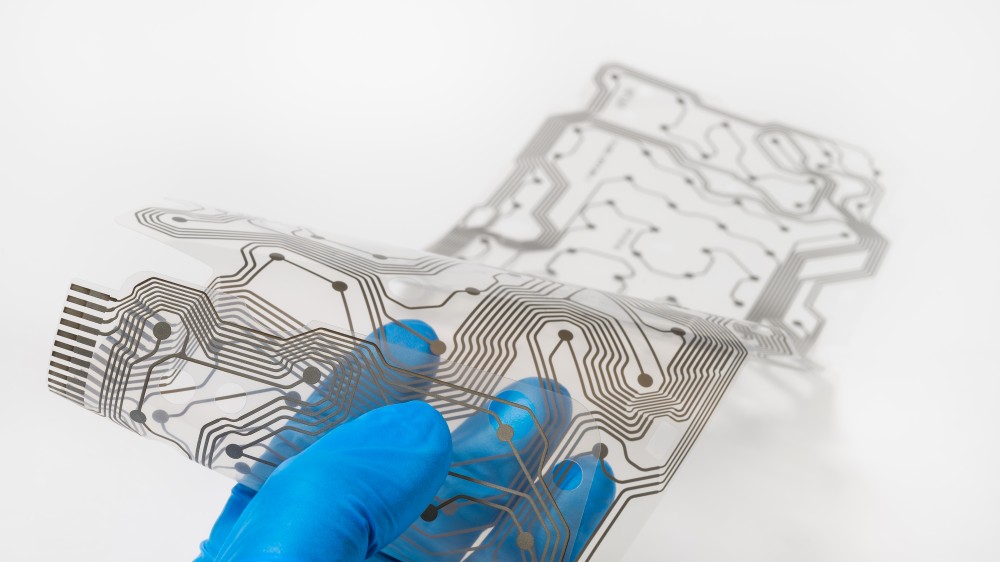

LEE-BED is an EU-funded Open Innovation Test Bed which provides European companies with easy, risk-free access to printed and embedded electronics. Via the user-friendly single entry point (SEP), customers with and without experience in the technology are granted direct access to leading European R&D facilities in the field of printed electronics. The process is simple. To start with, the technological and economic aspects of ideas are evaluated in three phases. Then, prototypes are built on selected test beds and, finally, know-how is transferred from the project partners to customers. The LEE-BED one-stop shop is thus the perfect incubator for advancing the development and spread of nano-based printed electronics.