Comprehensive efforts over the past few decades to improve thermal insulation and save energy have led to an increased use of insulating materials in the external components of buildings. These materials reduce the amount of heat lost from the building's interior via these components. In terms of building physics, this increases the probability that condensation will form on the outer surface of the façade due to the cooling effect of long-wave heat radiation during the night. The main prerequisite for microbial growth is sufficient moisture. However, the moisture content in exterior wall coatings is not a decisive factor for the growth of microorganisms because it has since been proven that a film of moisture on the surface is all they need to start growing.

The studies conducted to date indicate that hydrophilic coating systems are less susceptible to surface condensation. However, this is only true if they are able to release the absorbed moisture within a short period of time without it accumulating. It therefore follows that the risk of microbial growth could be reduced by optimizing the hygroscopic properties of the materials used for exterior plaster and in other external wall coatings.

Test setup

To evaluate what happens when condensation remains on the surface of the material, the researchers developed a test facility to help them simulate the nightly formation of condensation in the laboratory. Their experiments in the laboratory were able to reproduce very closely the conditions real building façades are exposed to temperatures below dew point were similar to those measured in the open-air test facility.

Because it is difficult to simulate nighttime heat loss by radiation in the laboratory, a cooling plate mounted to the rear of the test samples to cool them below their dew point, thus causing condensation to form on their surface. To optimize heat transfer from the test samples, which have a surface area of 25 cm2, the scientists used a heat-conductive paste to mount them to the water-cooled, copper heat sink. They then measured the temperature on the surface of the samples with ultra-flat pt100 sensors attached by hot-melt adhesive.

To simulate the behavior of a real façade in the laboratory, temperatures were selected that correspond to the natural drop in temperature associated with the formation of condensation. Similarly, the durations selected for the cooling phase, which range between one and six hours, are the same as might be expected in real-life conditions. These durations are determined by comparing the measured surface temperature with the dew point in the test chamber.

Taking the measurements

The refrigeration unit used to cool the samples was switched on about one hour before the test was started and set to a temperature between 6.5 and 12.5 °C. The temperature for each sample was chosen depending on its thickness and thermal conductivity, thus ensuring that all specimens had the same surface temperature at the beginning of the experiment. To record the environmental conditions in the test chamber, a humidity sensor and a pt100 temperature sensor were placed near f the specimen. Environmental conditions were kept constant throughout the measurements, with the air temperature of 23 °C and a relative humidity of 65 percent.

Five separate measurements were taken for each test setup, with cooling durations of one, two, three, four and six hours respectively, and approximately the same drop in temperature below the dew point. The amount of surface moisture was determined by dabbing the surface with a cellulose pad and comparing its weight before and after the experiment. A similar method is used in the open-air test environment. A new test was started after each measurement, using a fresh specimen in each case to prevent the accumulation of moisture. The previously-used samples were stored for at least one week in the test chamber to allow them to return to their original condition, while the tests continued using other specimens.

Results

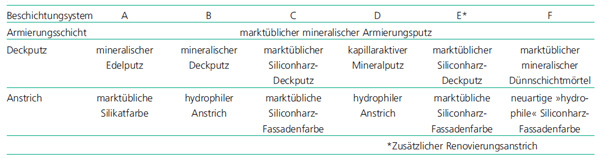

The measurements revealed that a high amount of surface moisture formed on System C, which was coated with a layer of highly hydrophobic silicon resin paint. The three other systems with more marked hydrophilic properties produced results with barely any moisture picked up by the cellulose pads. These findings correspond closely to the results of experiments conducted by the Hygrothermics Department on the same coating systems. Coating System E is a standard weatherproof system consisting of a silicon resin-based render and a silicon resin paint, comparable to System C but with the addition of two coats of renovation paint. After a cooling period of up to four hours, this system exhibited a very small amount of surface moisture. This proves that a suitable hydrophilic coating, even when applied to a hydrophobic substrate, can significantly reduce the amount of surface moisture forming after overnight condensation. However, if the cooling phase lasts longer than four hours, the coating is no longer capable of absorbing the condensation, and water droplets become clearly visible on the surface.

The novel hydrophilic silicone resin paint used in System F was unable to decrease surface moisture to the same extent as the mineral-based variants used in Systems A, B and D, but nonetheless reduced the amount of surface moisture by about a factor of four. This demonstrates that the ability of paste-like surface coatings to regulate surface moisture can also be improved by enhancing their hydrophilic properties.

The concordance of the results of these laboratory experiments with those obtained from the open-air tests has convinced the researchers at Fraunhofer IBP to establish this new method as a rapid, low-cost means of assessing the ability of coating systems to limit the accumulation of surface moisture. It is particularly adapted to the needs of companies wishing to enhance the properties of their coating products, enabling them to compile a shortlist of suitable candidates for further testing in the open-air facility. Although this demands more time and effort, it ultimately delivers data with a much higher statistical relevance.