Noise can significantly impair quality of life and comfort in everyday life. Conventional approaches to vibration and noise reduction often reach their limits. An innovative solution to this problem is vibroacoustic metamaterials (VAMM). VAMMs are structures with intermittently arranged, structural, dynamic and/or acoustic resonators.

MetaVib – making vibroacoustic metamaterials suitable for industrial use

Project goals

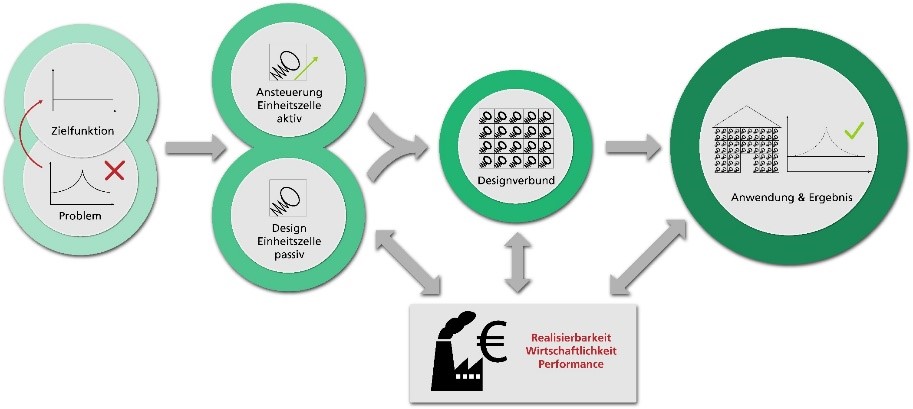

The “MetaVib” project aims at making vibroacoustic metamaterials suitable for use in industry. The Fraunhofer consortium of experts in structural dynamics (Fraunhofer LBF, Fraunhofer IWU), acoustics (Fraunhofer IBP, Fraunhofer IDMT), electroacoustics (Fraunhofer IDMT) and manufacturing technology (Fraunhofer IFAM, Fraunhofer IWU) makes it possible for the first time to consider the entire VAMM value chain.

The consortium’s sub-goals for making vibroacoustic metamaterials suitable for industrial use are defined as follows:

- Develop a design tool for the integrated virtual use of VAMM in your application scenario

- Assess the suitability of manufacturing processes for mass production (stamping, forming, plastic 3D printing, hybrid casting)

- Design a simplified and efficient signal processing system for active VAMMs

Current project status

In the “MetaVib” project, manufacturing technologies for the industrial application of vibroacoustic metamaterials are being studied. For metallic structures, new forming production process chains are being developed to manufacture high-precision filigree structures and integrate VAMM in sheet metal and car body components. When it comes to sheet metal forming, the aim is to further refine the stamping process so that semi-finished sheet products containing VAMMs can be manufactured. This will reduce the scattering of resonator geometries to a defined minimum and also enable reproducible production. In areas where these processes reach their limits, for example in terms of the material or the geometries that can be produced, there are plans to cleverly combine them with typically slower processes, in particular 3D printing (plastic and metal).

Fraunhofer IBP's role in the project

In the “MetaVib” project, Fraunhofer IBP is responsible for developing methods for acoustic metamaterials using the application scenario of pipe silencers and silencer baffles as an example.