Numerical algorithm for developing cost-efficient and environmentally friendly sound absorbers

If a room is hot and stuffy, if colleagues are on the phone all the time or a neighbor plays loud music, this can cause stress. The well-being and health of people in living areas and offices depend not only on the climatic conditions, but also on the acoustics. This is where absorbers come into play.

How can absorbers be improved?

Although such absorbers are already widely used in the building industry, they also have some disadvantages: the materials used to make certain types of absorber are harmful to the environment. In addition, some materials - such as glass fiber reinforced plastics, mineral wool and certain foams - have a low inherent strength and therefore need additional supporting structures. Furthermore, most absorber materials are not easy to shape. It is difficult to make rounded edges or complex geometries.

Optimization algorithm facilitates development

The development of new sound absorbers involves numerous experiments and measurements, which are time-consuming, costly and sometimes inaccurate. In this project, a research group at Fraunhofer IBP has developed an optimization algorithm enabling effective sound absorbers to first be developed on a computer.

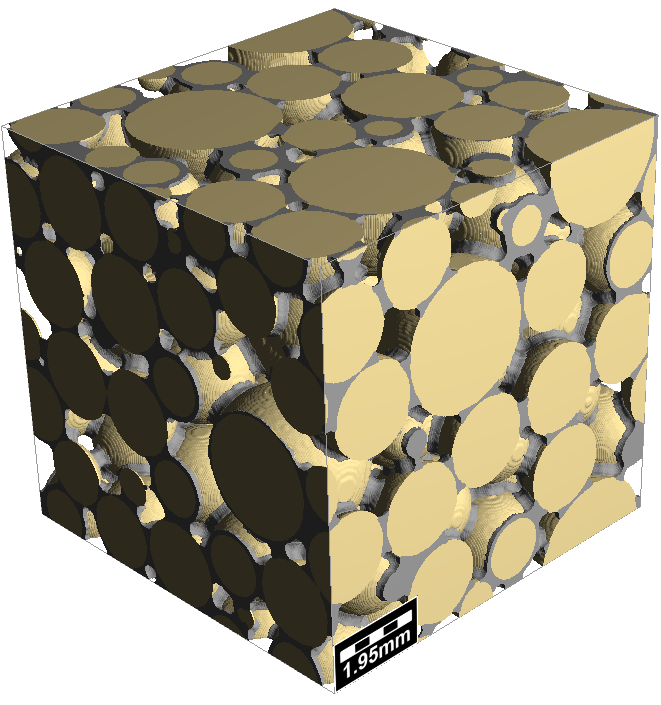

A numerical optimization algorithm considers geometric material properties such as packing density, porosity, particle size distribution or flow resistance. It correlates this information with physical properties such as the sound absorption coefficient. With this method, the geometric properties of materials can be optimized in order to maximize sound absorption. Furthermore, it is possible to predict these properties purely mathematically at a very early stage in the development process. This reduces development efforts considerably. Instead of investigating the acoustic properties of different grain sizes in a time-consuming process through tests, they can now be predicted via simulation with an acceptable amount of computing effort. The sound absorber is only manufactured and tested in the laboratory once the effects have been methodically investigated by simulation.

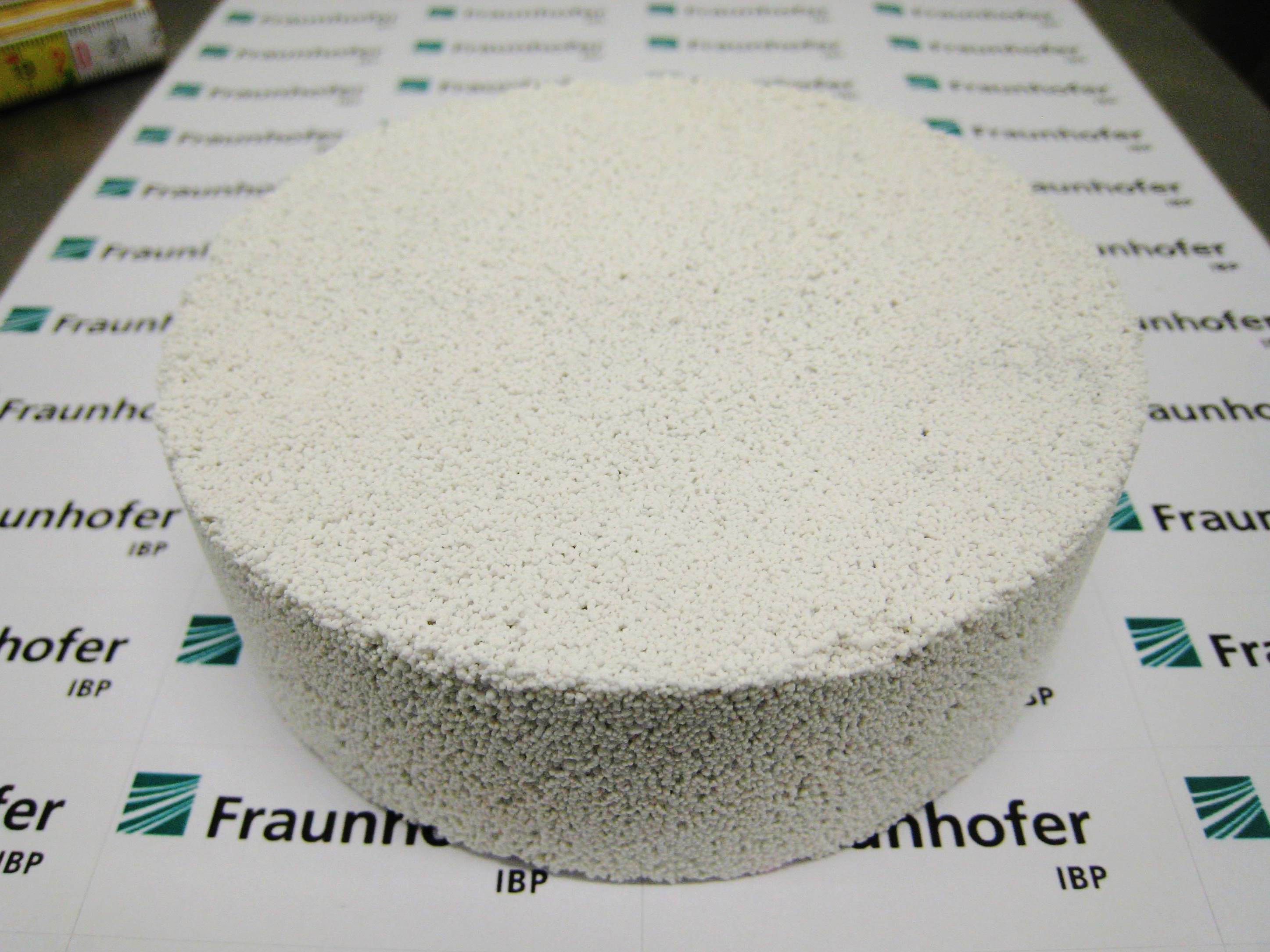

Sound absorbers five times cheaper but with the same performance

With the aid of the simulation software, the scientists at Fraunhofer IBP have developed a sound absorber that is excellent value for money compared to those currently on the market. Construction companies have to pay about five times as much for ones available on the market - with a similar sound absorption coefficient. The innovative sound absorber is made from expanded glass grains that are bound inorganically. The grains are a lightweight aggregate made from recycled glass. In terms of environmental indicators such as global warming potential and gray energy, the material scores better than expanded vermiculite, perlite or expanded clay. Supplied as a ready-to-use mixture, the sound absorber can be applied directly to vertical surfaces such as walls.