An innovative processing technology

Recycling inorganic composite materials like concrete or refractory concrete and also sintered or “caked” combustion residues such as waste incineration ashes has so far only been possible to a limited extent. Teams of scientists from Fraunhofer IBP's Department of Inorganic Materials and Recycling have therefore been conducting research on the innovative processing technology of electrodynamic fragmentation (EDF) for several years. What makes this technology so special: the various constituents of the composite material can be separated in a highly selective manner, thus opening up new ways of recycling composite materials that could not be fully recycled up till now.

Aggregates recycled from concrete rubble

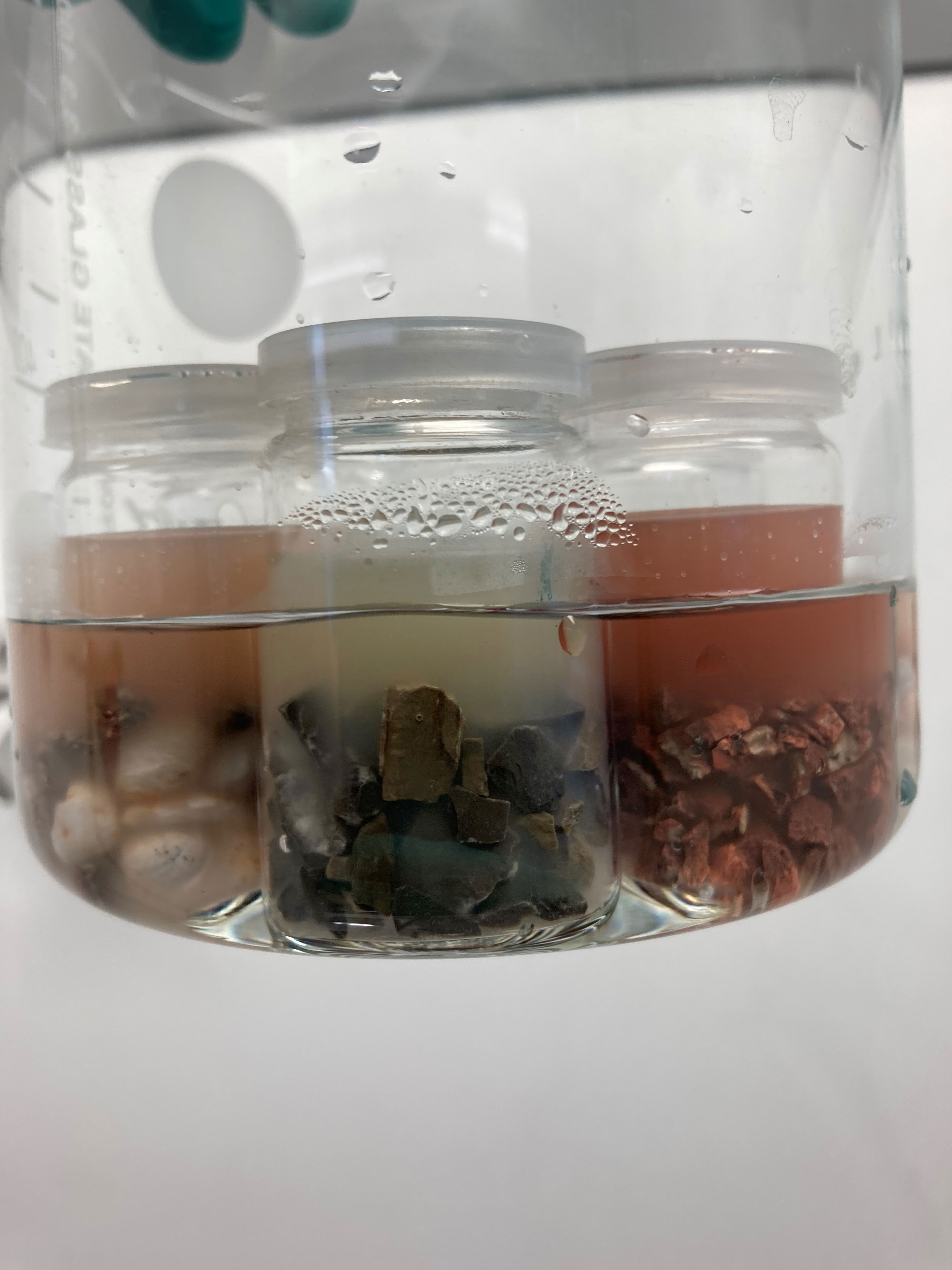

Mechanical processing methods like jaw crushers or impact mills can “only” crush concrete rubble but not selectively separate it: the aggregates still have hardened cement paste and sand adhering to them, which has drawbacks when it comes to their reuse in concrete formulations - such as higher water requirements during processing and lower compressive strengths in the end product. DIN EN 12620 and DIN 1045-2 therefore impose restrictions on the use of recycled materials obtained by conventional methods.

By contrast, these restrictions do not apply to recycled aggregates obtained when concrete rubble is processed by EDF. Since the concrete rubble is selectively separated, only minor quantities of foreign material, if any, still adhere to the aggregates. With aggregates recycled in this way, it is possible to produce concretes whose properties are almost identical to concretes made from primary or natural aggregates. This opens up new and far-reaching opportunities with regard to a closed material cycle in the construction industry.

A standard for the circular economy of the future

The categories defined in current standards governing the evaluation and use of recycled aggregates only apply to a limited extent to the aggregate classes obtained by EDF. This is because selective separation means that the quality of the recycled aggregate largely depends on the proportion of cement paste contained in the respective aggregate classes. These aggregates therefore need to be categorized separately in order to determine the best way of using these recovered raw materials.

For this reason, Fraunhofer IBP researchers collaborated with DIN and external partners from the concrete industry to develop a new DIN SPEC, in which they present a test method for quantitatively determining the content of cement paste adhering to the separated aggregates. In other words: based on the results of the test method, in the DIN SPEC the team proposes a clear evaluation and categorization of the separated aggregates. In the future, this categorization will enable the aggregates extracted from concrete rubble by EDF to be returned to the material cycle in line with their potential.