Adhesives and sealants with elastic properties are of significant importance for modern construction engineering. The range of application is versatile and includes all construction sectors, whether for joining building components, sealing joints or openings. As concerns their application-specific properties such as adhesion, tear resistance and durability, significant progress has been made in adhesives and sealants in the past years. Their acoustic performance has so far been in the background, although joint sealing and adhesive connections are a substantial sound transmission path, especially in building services and installations. In this context, the connections to the building, through which vibrations and structure-borne sound are transmitted into the building structure, are particularly important. Elastic intermediate layers, such as joint seals, can considerably reduce sound transmission at the joints, since they act as vibration-insulating elements due to their elasticity. One prerequisite, however, is that the adhesives and sealants have adequate acoustic properties and that the building components involved are acoustically matched to one another.

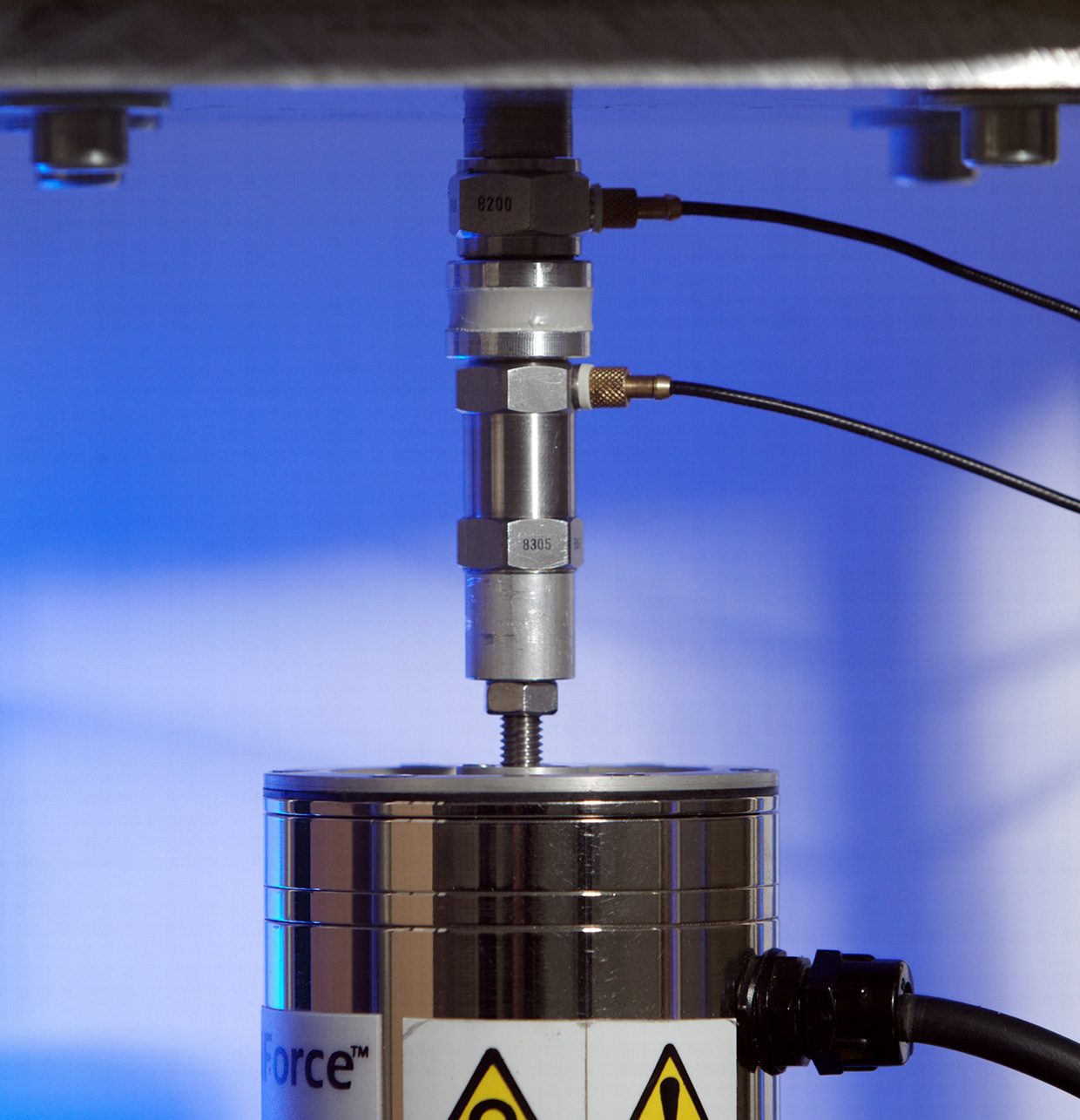

The objective of the joint research project was to investigate in detail the properties of adhesives and sealants and their interaction in practice. In addition to dealing with questions of application, the focus is on the development of innovative acoustically optimized materials. It can already be seen that there are significant differences in acoustic properties between the materials used at present. This finding alone will contribute to improve the acoustic design quality. Development work, however, will be continued. Of significant importance here is a measuring device with which the acoustically substantial properties of adhesives and sealants, especially the modulus of elasticity and loss factor, can be determined in dependence of frequency. Based on these measurement results, it is now possible to formulate the correlations between the chemical composition, manufacturing process and required acoustic properties. With appropriate products, for example the noise of the neighboring permanent shower will no longer be audible.