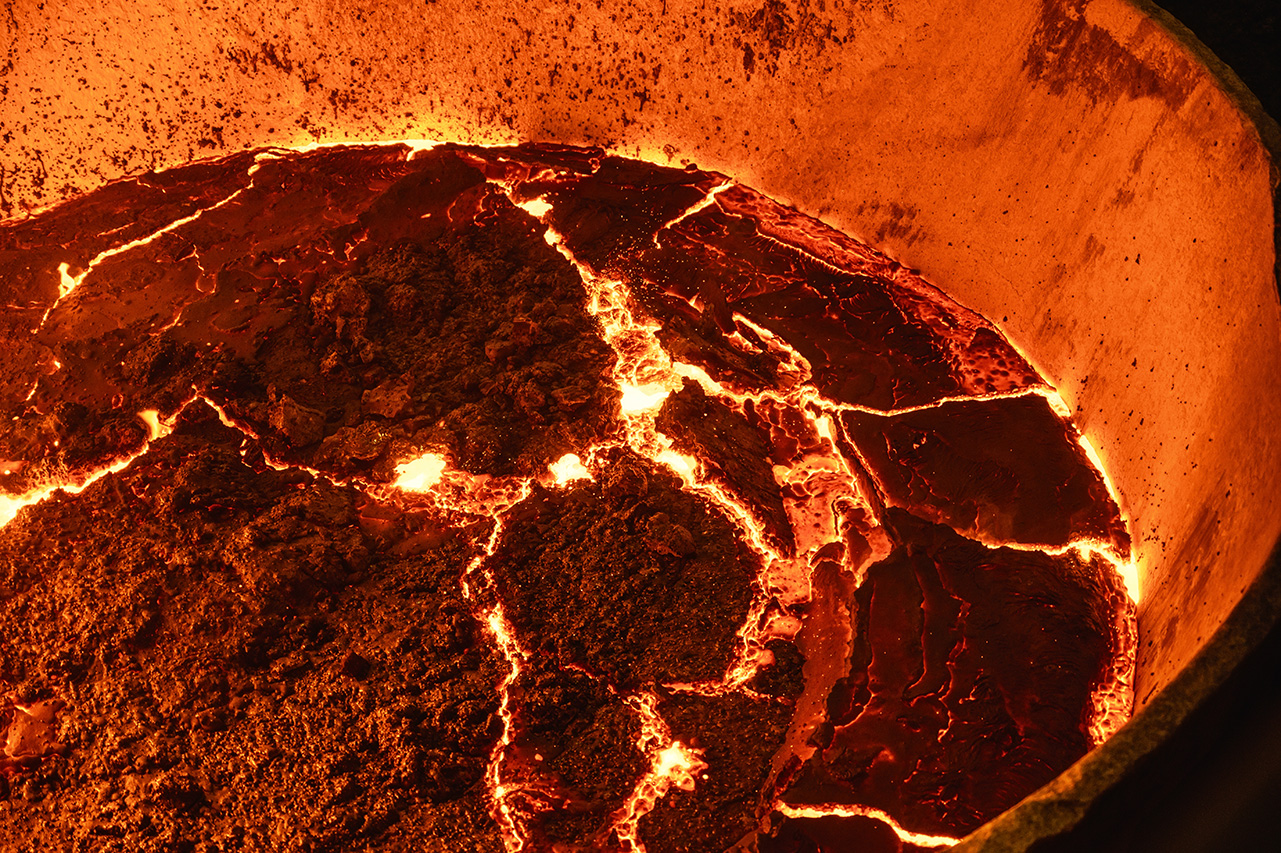

In the RESycling project, Fraunhofer IBP’s task is to develop practical solutions for processing and recycling hot metal desulfurization slags (abbreviated to RES in German, hence the name “RESycling”) together with collaborative partners. The joint project is funded by the German Federal Ministry of Education and Research (BMBF) as part of the measure to “Avoid climate-relevant process emissions in industry (KlimPro-Industrie)” and coordinated by Fraunhofer IBP. By processing hot metal desulfurization slags, valuable raw materials can be obtained. Three industrial sectors are testing the usability of these materials - namely the steel, cement and fertilizer industries. IBP has been tasked with processing the slags, optimizing the process steps, determining climate-relevant process emissions, and performing an analysis of technological and economic aspects.

RESycling - driving climate protection forward in three branches of industry thanks to smart technology for processing hot metal desulfurization slags

Project goals

Thanks to a multi-stage process involving electrodynamic fragmentation (EDF) and the ENSUBA process developed at Fraunhofer IBP, hot metal desulfurization slags will be treated in a way that will unlock the potential of the slags in terms of raw materials. To be more specific, the pig iron contained in the slags can used by the steel industry, the sulfates by the fertilizer industry, and the minerals by the cement industry as alternative raw materials. Implementing the process can sustainably reduce process emissions in the above-mentioned industries and support existing zero-waste strategies with regard to resource efficiency.

The project aims at upscaling the process from laboratory to pilot plant scale in order to assess its feasibility for use in industry. The process will be monitored throughout the project and evaluated as part of a life cycle assessment.

Current project status

Fraunhofer IBP is coordinating the RESycling project. Besides administrative tasks, the focus is on the following three scientific aspects:

- Comprehensive characterization of the hot metal desulfurization slags and separation of the pig iron by electrodynamic fragmentation (EDF) with the goal of returning the iron to the steel industry.

- Transfer and adaptation of the ENSUBA process, as well as the design of a pilot plant to scale up the process so that the raw materials can be used by the fertilizer and cement industries, and evaluation of the suitability of the process for use on (a large) industrial scale.

- Hot-spot analysis to optimize the process and quantify the reduction in climate-relevant process emissions.

- Economic assessment based on a comparison of running costs and revenues.

Project partners

- Fraunhofer Center for Chemical-Biotechnological Processes CBP

- Weihenstephan-Triesdorf University of Applied Sciences

- Südbayerisches Portland-Zementwerk Gebr. Wiesböck & Co. GmbH

- thyssenkrupp MillServices & Systems GmbH