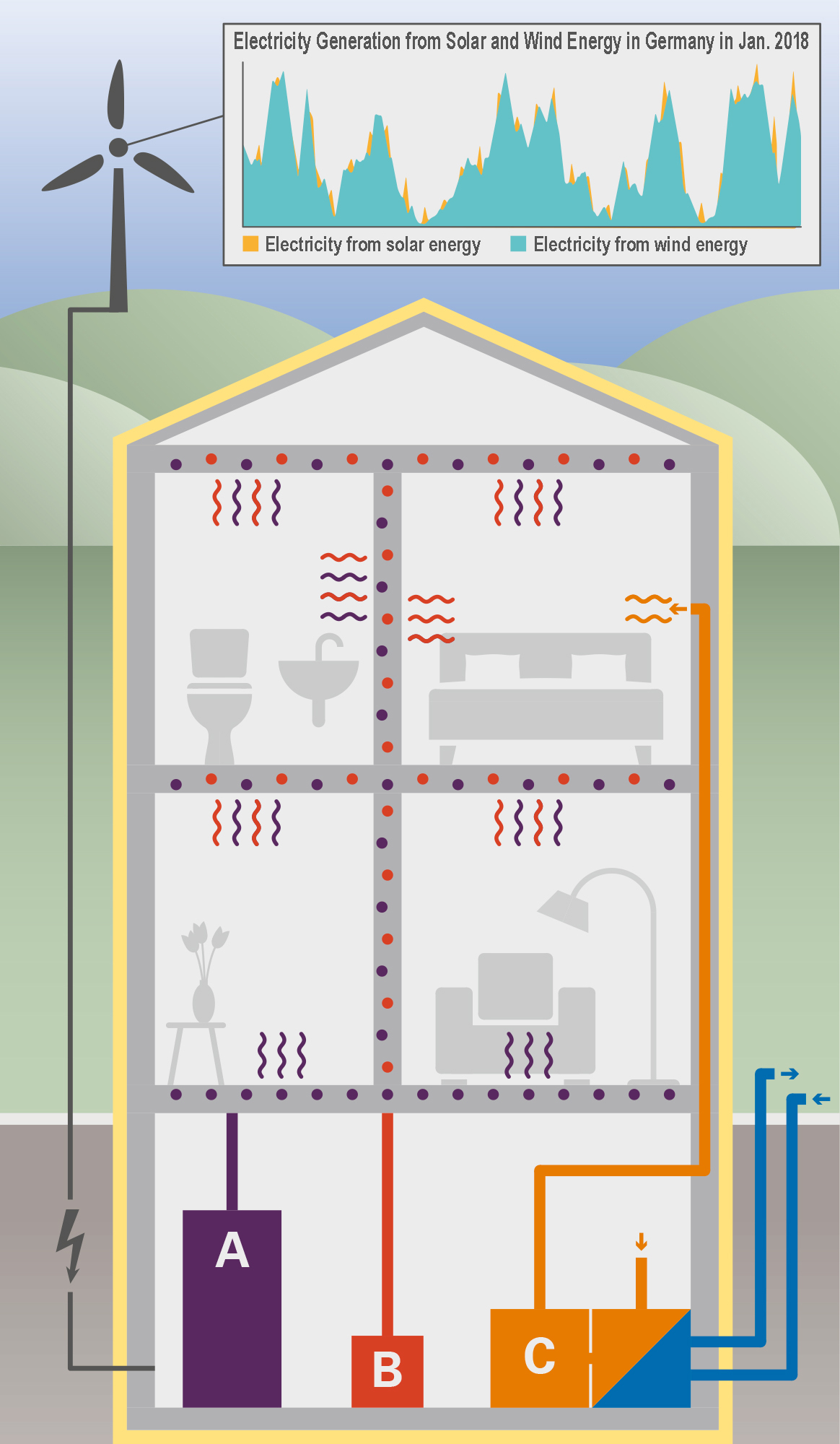

Wind energy now accounts for the largest percentage of electricity generated by renewable energies in Germany. Especially during periods with high winds in winter, the German electricity grid provides an oversupply of electricity that results in very low or even negative prices on the electricity exchange. In some regions, wind farms must be throttled or even temporarily shut down completely to ensure grid stability. With their large thermal storage masses, buildings in Germany offer enormous potential for heat storage. Since wind power will play an important role in the electricity grid of the future and is available in excess - especially during periods with high winds in winter - the time coincides closely when highly efficient buildings need to be heated and when surplus power is available. In the future, buildings with wind-powered heating 2.0 will be able to meet their energy needs in an environmentally and system-compatible manner by generating heat from renewable surplus electricity. At the same time, they will be able to contribute to the successful implementation of the energy turnaround. For the electricity grid, system compatibility also results from the fact that buildings with wind-powered heating 2.0 can do without electricity for heating purposes during longer phases of high grid utilization (one to two weeks).