Building physics testing

Fraunhofer IBP is focused on research, development and testing in all fields of building physics. Based on the competence of more than 350 scientists, engineers and technicians numerous outstanding testing resources and measuring instruments are available. Knowledge, experience and creativity can be offered as the keys to innovative products and sustainable quality of buildings.

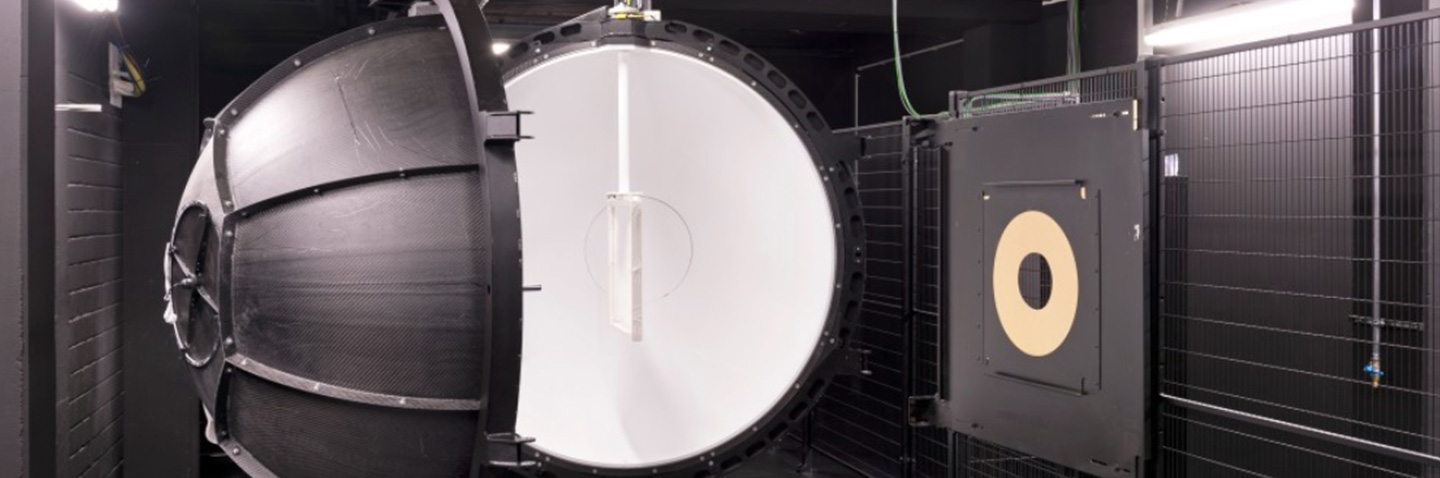

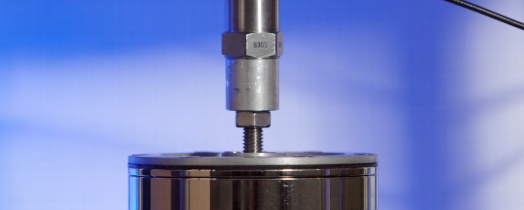

We carry out complex building physics studies at our efficient and well-equipped laboratories and test centers and at our outdoor testing site in Holzkirchen, which to the best of our knowledge is the largest facility of its kind. Modern laboratory measuring techniques and computational methods help researchers develop and optimize building products for practical applications. We also carry out experiments in environmental test chambers, simulation facilities and existing buildings to assess components and overall systems for new buildings and renovation projects based on the principles of building physics.

Fraunhofer IBP has been approved by the German building inspection authorities as a testing, monitoring and certification center for building materials and buildng techniques in Germany and the rest of Europe. Five of the institute's test laboratories have been granted flexible accreditation by the German accreditation body Deutsche Akkreditierungsstelle GmbH (DAkkS) in accordance with DIN EN ISO/IEC 17025. This entitles them to develop new test methods and to modify existing methods.