Faster, higher, lighter: we develop innovative lightweight materials for a sustainable future

The construction industry's interest in lightweight building materials, i.e. materials with a low density and low weight, has grown steadily in recent years. The main reason for the rising demand - besides being able to save on materials - is the fact that these primarily-porous materials have good heat-insulating properties.

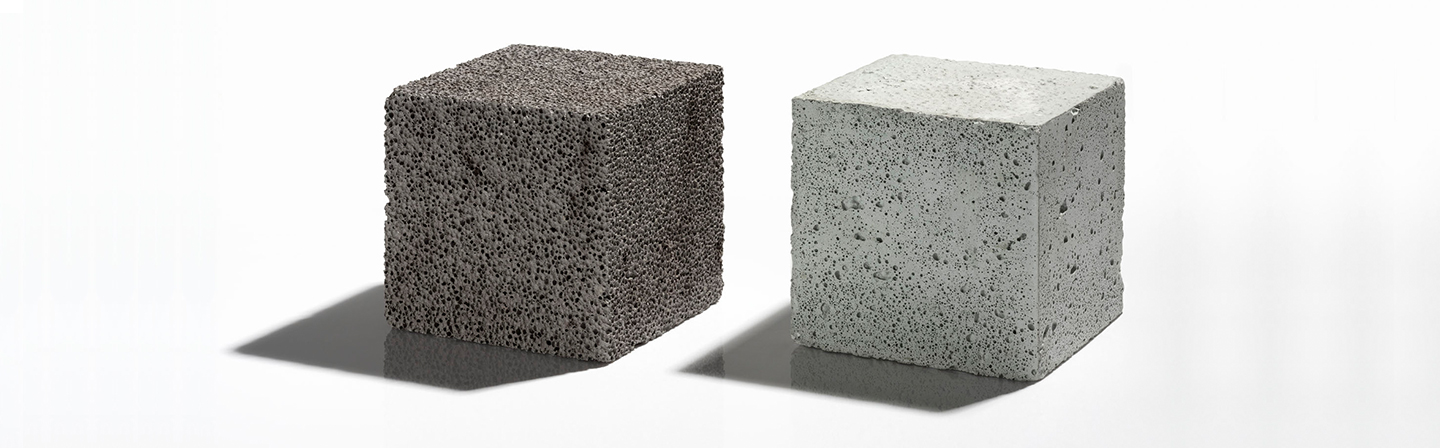

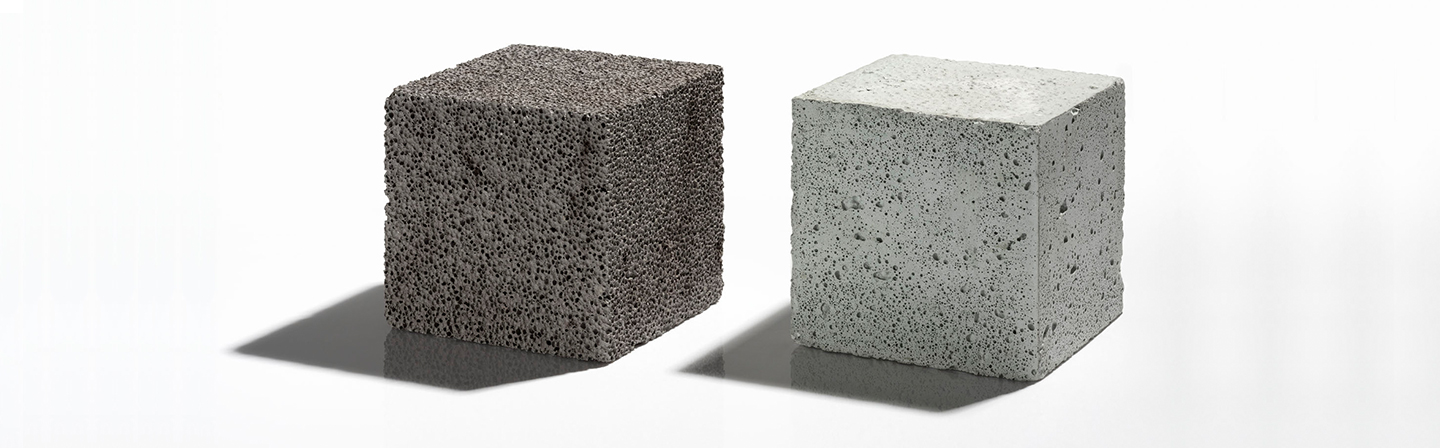

Some lightweight building materials consist of a binder matrix with a lightweight or porous aggregate - such as expanded clay, expanded glass, foam glass, pumice or perlite. To improve stability, lightweight or insulating concretes can be additionally reinforced with lightweight textile knitted fabrics or fibers. Other lightweight materials already consist of a porous matrix and may contain additional porous aggregates.

Lightweight materials to suit requirements

One of the best-known lightweight building materials is aerated concrete. However, there are also other products, such as foamed concretes or cements, that -unlike aerated concretes - do not need to be autoclaved. These inorganic foams can be used to fill cavities in more solid building materials or as stand-alone foamed concretes.

Our experts research and develop foaming technologies as well as methods for making lightweight materials porous. We are also working on granulation techniques for producing porous inorganic granules, with the aim of using these as lightweight aggregates in lightweight concretes or as a loose filling material. Last but not least, we also develop special lightweight concrete formulations tailored to your specific needs.

Develop building materials with us for a sustainable future!